Opening and Closing Forces on Fire Doors

Since 2010, all fire doors installed in New Zealand must comply with NZS 4520:2010, which includes a clause about measuring opening and closing forces. This clause has always been part of the Door Manufacturers Installation installer’s declaration forms, and it has been the installers’ responsibility to ensure that the installation complies with NZS 4520.

However, in 2023, Auckland Council requested that the measurements be noted on all declaration forms to ensure compliance. Door Manufacturers have followed the council’s instruction and updated forms to confirm and note these pressures before the installer signs off.

Requirement from 2.2.1 – NZS 4520:

2.2.1.2 Door operational forces for fire doors

Except for doorsets incorporating floor or head springs (for which the testing of frictional forces is not practicable), when continuously applied perpendicular to the face of the door leaf at a radius of 700 mm from the pivot centre, and before the closer arm is attached, the force required to:

(a) Move the door leaf from the fully closed position to the fully open position and return to the strike plate shall be not more than 2 N; and

(b) Bring the door leaf to the fully latched condition shall be not more than 20 N.

NOTE – These forces exclude the effects of differential building pressures

For Point B (20 N):

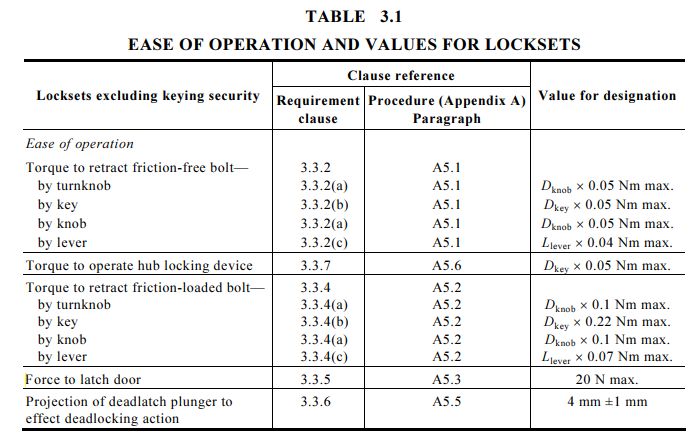

Our Lockwood Standard Mortice locks series 3500 and 3700 are tested on AS 4145.2—2008, which states that the ease of operations - Locksets and hardware for doors and windows should conform to the force requirement of 20N to latch the door. This has also been stated in our lock catalogue, confirming compliance with the standard.

(Table reference from AS 4145.2)

Note that the locks are tested for this force and confirmed. However, using non-bearing hinges and seals can sometimes impact this force. Also, note that these forces should exclude the effects of differential building pressure.

Point A (2 N):

If the latch is already retracted, the force required to fully open and close the door depends more on the door mass and the hinges rather than the mortise lock itself. Based on this information, it appears that this measurement should be performed by the installer, as it is more related to the appropriate selection of hinges and door mass than to the lock.

A pressure gauge is used to measure these forces on-site, with the door closer arm detached and applying force to retract the latch and open/close the door.

The main conveyance is that locks are tested for standards that need to comply with these force requirements. As a manufacturer, we note this in the catalogue and confirm compliance. However, also note that this force may be affected by external factors such as those listed above, which are not related to the lock itself. Installers and manufacturers need to pay attention to these factors.

Related products

Selector® Series Commercial Mortice Locks

A comprehensive range of cylinder mortice locks suitable for heavy duty use in industrial and commercial applications.- Lockwood

Lockwood 3570 Series Electric Mortice Lock

Constructed from high grade zinc alloy, with a stainless steel latch bolt and face plate and is suited for all commercial applications.